Fill out your details and our executive will get in touch with you soon.

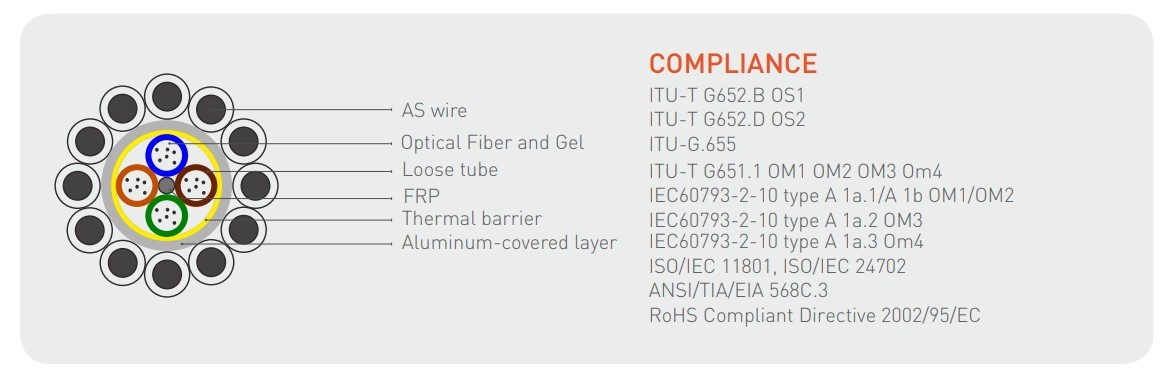

Fibre Optic Overhead Group Wire Optical Ground Wire (OPGW) is used in power utility for dual function as a ground or static wire and a path for transmission of voice, video or data signals through optical fibres allowing for fast, reliable and cost effective installations.Fibres are placed in a central stainless steel tube with water-resistant jelly filling; it is inserted into an aluminium pipe which provided added crush protection and increasing the conductivity. Over it one or two layers of aluminium coated steel wire or aluminium wire or aluminium alloy wire are stranded, stranded wires are selected to optimize mechanical and electrical properties of cable. They have high tensile load, long span and high crush resistance. Their small diameter and light weight minimize load to the tower.

Fibre Optic Overhead Group Wire Optical Ground Wire (OPGW) is

used in power utility for dual function as a ground or static wire and a

path for transmission of voice, video or data signals through optical

fibres allowing for fast, reliable and cost effective installations. Fibres

are placed in a central stainless steel tube with water-resistant jelly

filling; it is inserted into an aluminium pipe which provided added crush

protection and increasing the conductivity. Over it one or two layers of

aluminium coated steel wire or aluminium wire or aluminium alloy wire

are stranded, stranded wires are selected to optimize mechanical and

electrical properties of cable. They have high tensile load, long span

and high crush resistance. Their small diameter and light weight

minimize load to the tower.

AL layer | 53.0% |

AS Wire, 12 no. | 20.3% AS wire |

| Cross Section | 100.00 mm2 |

| Section of AS Wire | 74.00 mm2 |

| Section of AL Tube | 27.00 mm2 |

| Rated Tensile Strength (RTS) | 89.1 kN |

| DC Resistance | 0.559 Ω/km |

| Short Time Current ( 0.3s, 50℃~200℃) | 13.4 kA |

| Bend Radius (Short Term) | 141 mm |

| Bend Radius (Long Term) | 282 mm |

| Short Time Current Capacity (50℃~200℃) | 53.8 kA2S |

| Operating Temperature | -40℃ ~ +85℃ |

| Installation Temprature | -10℃ ~ +50℃ |

| Item | Unit | Description |

| Attenuation at 1550 nm | dB/km | ≤0.25 |

| Attenuation at 1620 nm | dB/km | ≤0.30 |

| Dispersion at 1530 -1565 nm | ps/nm. km | 2.6-6.0 |

| Dispersion at 1565 - 1625 nm | ps/nm. km | 4.0-8.9 |

| PMD | ps/ sqrt Km | < 0.2 |

| Fiber Proof Test Level | Kpsi | 100 |

| Mode Field Diameter at 1550 nm | µm | 8.6 ± 0.4 |

| Core Concentricity Error | µm | ≤0.8 |

| Cladding Diameter | µm | 125 + 1.0 |

| Cladding Non-Circularity | % | ≤1.0 |

| Dispersion Slope at 1550 nm | ps/sqnm.km | < 0.045 |

| Fibre Number | Fibre Colour | ||

Fibre 1 | Blue | Fibre 1 | Red |

Fibre 2 | Orange | Fibre 1 | Black |

Fibre 3 | Green | Fibre 1 | Yellow |

Fibre 4 | Brown | Fibre 1 | Violet |

Fibre 5 | Slate | Fibre 1 | Rose |

Fibre 6 | White | Fibre 1 | Aqua |

Fibre 13 and higher the colour code is repeated with added black stripe or dash | |||

| Part Number | Fibre Count | Outer Diameter (mm) | Weight (N.W Kg ) | Weight (G.W Kg) |

| 3117-41048FXXCL | 48 | 14.10 | 591 | 2600 |